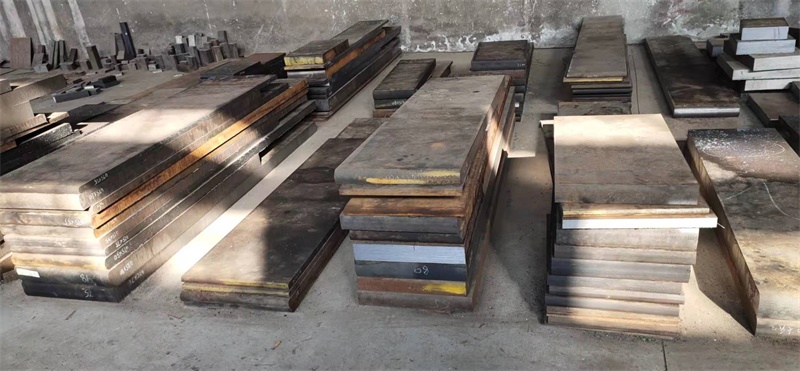

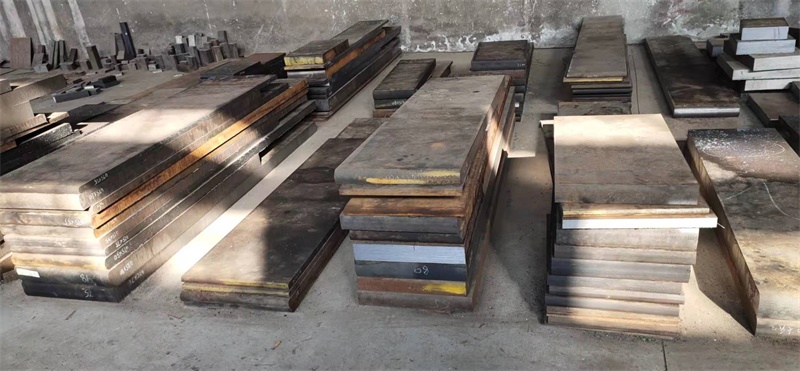

冷作模具钢是用来制造使金属冷变形的模具。冷作模具钢大体可分为:低合金冷作模具钢、中合金冷作模具钢、高合金冷作模具钢。

Cold work die steel is used to make dies that cold deform metals. Cold working die steel can be divided into low alloy cold working die steel, medium alloy cold working die steel and high alloy cold working die steel.

低合金冷作模具钢,以 CrWMn 为代表,包括9Mn2V、9CrWMn、CrWMn、MnCrWV、7CrMn2Mo、7CrSiMnMoV等。这类钢的主要特点是工艺性好、淬火温度低、热处理变形小、强韧性好,并且有适当的耐磨性。虽然合金含量较低,小于5%;但碳含量较高,达到中合金冷作模具钢,以Cr5Mo1V(A2)为代表,包括Cr4W2MoV、Cr5Mo1V等。由于碳含量相对低、铬含量低,属于过共析钢。这类钢中的碳化物以Cr7C3型为主,并有少量M 6 C和MC型,具有耐磨性好和热处理变形小的特点。

Low alloy cold working die steel, represented by CrWMn, includes 9mn2v, 9crwmn, CrWMn, mncrwv, 7crmn2mo, 7CrSiMnMoV, etc. The main characteristics of this kind of steel are good processability, low quenching temperature, small heat treatment deformation, good strength and toughness, and appropriate wear resistance. Although the alloy content is low, less than 5%; However, the carbon content is high, reaching medium alloy cold working die steel, represented by Cr5Mo1V (A2), including Cr4W2MoV, Cr5Mo1V, etc. Due to the relatively low carbon content and low chromium content, it belongs to hypereutectoid steel. The carbides in this kind of steel are mainly Cr7C3 type and a small amount of M6C and MC type. It has the characteristics of good wear resistance and small heat treatment deformation.

高合金冷作模具钢,以Cr12Mo1V1(D2)为代表,包 括Cr12、Cr12W、Cr12MoV、Cr12MoV1、W6Mo5Cr4V2、5Cr4W3Mo2VNb、6W6Mo5Cr4V等。传 统 的 Cr12 系 冷 作 模 具 钢 如 Cr12MoV、Cr12Mo1V1是我国20世纪末常用的冷作模具钢,热处理后变形小、耐磨性高、承载力大,长期以来在国内大中型冷作模具中得到广泛应用。

High alloy cold working die steel, represented by Cr12Mo1V1 (D2), includes Cr12, cr12w, Cr12MoV, cr12mov1, W6Mo5Cr4V2, 5cr4w3mo2vnb, 6w6mo5cr4v, etc. Traditional Cr12 cold working die steels such as Cr12MoV and Cr12Mo1V1 are the most commonly used cold working die steels in China at the end of the 20th century. They have small deformation, high wear resistance and large bearing capacity after heat treatment. They have been widely used in large and medium-sized cold working dies in China for a long time.

当硬度相同的情况下,故中合金的冷作模具钢和高合金冷作模具钢切削加工相对会比低合金模具钢困难。

When the hardness is the same, the machining of medium alloy cold working die steel and high alloy cold working die steel is relatively more difficult than that of low alloy die steel.

以上这些内容就是关于冷作模具钢https://www.jnqhmj.com的相关内容,如果您想要了解更多内容,欢迎联系在线客服,我们必将竭诚为您服务。

The above contents are about cold working die steel https://www.jnqhmj.com If you want to know more, please contact online customer service, and we will serve you wholeheartedly.

上一条:

SLD8冷作模具钢有很强的韧性

下一条:

锻造模具需要使用什么模具钢